Shell and HyET Solar have conducted a study at the National Renewable Energy Laboratory (NREL) in Denver (US) on the economic potential of HyET Powerfoil in desert based utility scale (100 MW) PV powerplants.

Technical tests indicated advantages of using power foil concept in hot environment, the Powerfoil product passed NREL’s accelerated aging tests (C-AST protocol). On the cost side, it was shown that under key assumptions made, HyET Powerfoil technology may be cost competitive with c-SI cell technology at 18% efficiency.

The study confirmed a degradation rate of <1%/yr (showing that no difference in degradation rate exists with a-Si on glass technology) and a very low temperature coefficient.

Low temperature coefficient

Determination of the temperature coefficient requires investigation of the reduction of conversion as a result of an increased temperature. Therefore, a set-up was used in which flash testing is performed on modules that are heated from room temperature to 75°C. The flash tester used is the SPI-SUN Simulator 5600SLP, of which the flash testing was set to the STC irradiation of 1000Wm−2. A structure was placed on top of the flash tester through which hot air was circulated to increase the temperature of the modules. The temperature measurements were performed using 16 Omega SA-1 thermocouples on the back of the modules. A high-end quality crystalline silicon reference cell was added to investigate the difference in temperature coefficients.

Results

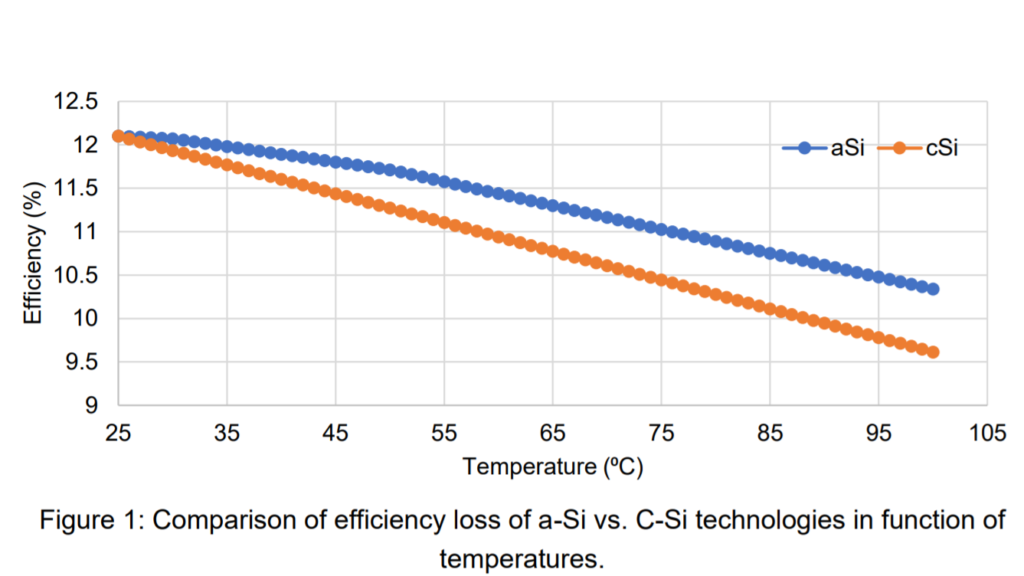

The result of the temperature coefficient tests for both amorphous silicon and crystalline silicon are provided in Figure 1. The results were extrapolated from 75°C to 100°C as the experiment could go to a maximum temperature of 75°C. What can be observed is that amorphous silicon has a significant advantage over crystalline silicon with regards to the temperature coefficient. The amorphous silicon temperature coefficient has three different slopes: −0.00049°C−1 between 25°C to 30°C, −0.00148°C−1 between 30°C to 50°C and −0.00227°C−1 between 50°C to 75°C. In contrast, crystalline silicon has a consistent temperature coefficient of −0.00274°C−1, which is higher than the steepest slope for amorphous silicon. Important to point out is that the NREL scientist Dr. Paul Ndione that led the measurements insisted that the crystalline silicon sample was in the top and most C-Si PV technologies on the market. Considering a temperature of 85°C, Powerfoil has at least a 6% lower power loss than crystalline silicon technology.

Figure 1: Comparison of efficiency loss of a-Si vs. C-Si technologies in function of temperatures.

Conclusion

It can be concluded that Powerfoil has a significant advantage compared to crystalline silicon panels at high operating temperatures (e.g. solar farms in desert environments). For a 100 MW solar PV power plant, the a-Si Powerfoil technology would produce 6 MW more than C-Si traditional PV technology, that is with top-class and costly technology so the CAPEX would be much higher for the C-Si technology. If a lower cost C-Si PV solar panels would be selected, the overall energy loss vs. the a-Si Powerfoil would be even higher.

Pls. contact HyET us at max.middelman@hyetsolar.com to receive a copy of the study report